Projections show that the global rapid prototyping market will reach a value of $2.283 billion by 2028. Prototyping is a key component of product design.

It allows you to test out your product to see how well it performs, and from this, you can determine any changes that need to be made to the final product. Rapid prototyping is a popular method for this due to the advantages it brings.

So what are the benefits of rapid prototyping? Keep reading to find out.

Speed

As the name suggests, rapid prototyping is one of the fastest prototyping methods available. In the manufacturing industry, speed is key, so saving time at any stage of the product development process is beneficial.

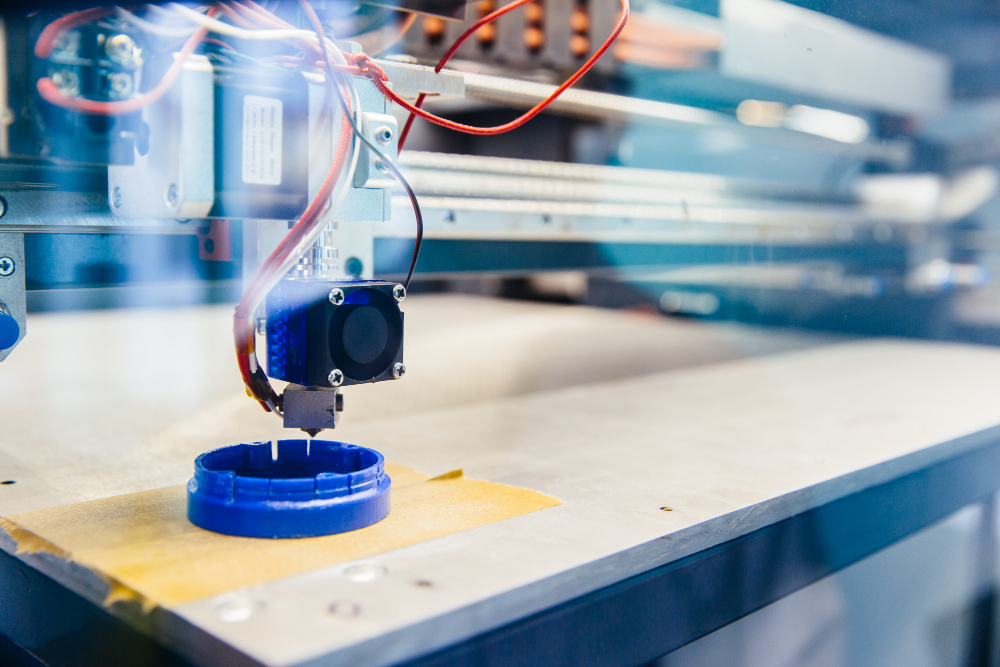

3D printing is generally one of the fastest methods of fabricating parts, requiring little machine setup time. As parts are printed from CAD files, changes can also be made very quickly. You can even generate models using devices like these 3D scanners.

Cost

3D Printing is typically cheaper than CNC machining or other types of manufacturing. This comes down to several factors such as:

- Material procurement

- Programming tool paths

- Setup configuration

- Machine running and monitoring

- Finishing work

The entire manufacturing process for 3D printing is much simpler as most of it is computer-controlled. As it’s a form of additive manufacturing, it also generally uses less raw materials than other types.

Comprehensive Testing

Engineers can carry out more thorough testing through rapid prototyping than is usually possible. 3D printing allows for very complex parts to be produced and can often form parts that other manufacturing techniques simply aren’t capable of.

Through 3D printing, you can easily create parts with thin walls, sharp corners, and intricate patterns. As you can easily make changes to CAD files and print new parts, you can easily test multiple variations of a product. This will help you settle on the best final design. You can look at the trade-off between the aesthetic design and functionality of a product and simplify the design as needed.

Part Consolidation

Sometimes you might be testing a product that will need to be made up of multiple parts for end use. This way, you can get testing done quicker and better assess these individual parts to see what changes you should make. This is both cost-effective and ideal for trying out different part designs.

Some 3D printing processes are also suitable for manufacturing end-use parts. With part consolidation in the testing stage, you can lower the overall product development costs.

Test Materials

Another key advantage of 3D printing over other manufacturing methods is that it allows you to use almost any material. You can create prototypes from things such as:

- Plastics

- Metals

- Wood

- Carbon fiber

- Paper

- Resins

- Graphite

With all these options, you can test out various material options with a range of properties. It’s not uncommon to have a product in mind without having already decided on the material, so this makes it easy to compare how different materials perform.

Do You Need Rapid Prototyping?

There are plenty of prototyping methods you can use, but rapid prototyping is often the best. It’s quick, cost-efficient, and gives a lot of flexibility when it comes to testing products. If you want to produce the best-finished piece possible, rapid prototyping is ideal.

For more tech articles, check out some of our other blog posts.